How Collecting Data and Engaging Your Workforce Can Unlock Sustainability Solutions

In the fourth webinar of the People First series presented by The Packer and Equitable Food Initiative (EFI), EFI’s Senior Workforce Development Facilitator Lilian Autler moderates a discussion between Kieran Ficken of sustainability consulting firm Measure to Improve (MTI) and Alex Lopez and Jeff Madu of Windset Farms®. Their discussion explores the process of outlining and implementing sustainability initiatives in a greenhouse setting, the importance of collecting data in creating sustainability solutions and practical first steps that are accessible for all types of agriculture companies. The panel also shares real world experiences and learnings from a collaborative waste reduction program that is in progress at Windset Farms’ greenhouse operation in Santa Maria, California.

Watch the full webinar.

An Elastic Definition of Sustainability

Sustainability is clearly important to consumers as well as the continued success of the industry. Even so, establishing sustainable practices can prove to be a moving target for fresh produce companies as the bar for sustainability is raised with changing regulations, new technologies and new research. A working definition of sustainability that fluxes with those changes can help orient your company’s sustainability goals.

Jeff Madu, Vice President of Sales for Windset Farms, a greenhouse grower of premium quality tomatoes, cucumbers, strawberries and peppers in the United States and Canada, explains that the company works to reduce resource use and reuse and recycle everything possible at its greenhouse operations, including the condensation water and CO2 produced to grow the greenhouse fruits and vegetables.

“For Windset Farms, sustainability means farming, producing and delivering healthy vegetables in a circular economy. Whether it’s our water treatment system or packaging, our goal is to provide healthy and nutritious food amidst the demands of the increasing population on the delicate planet we live on.”

– Jeff Madu, Vice President of Sales, Windset Farms

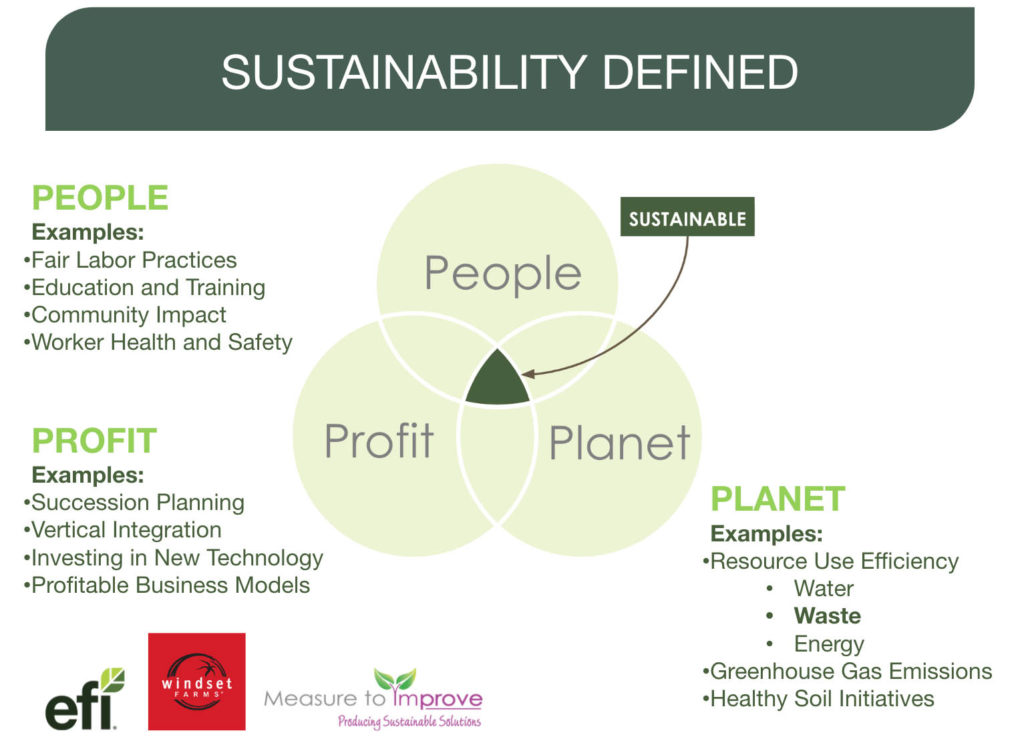

Kieran Ficken, Sustainability Program Manager with MTI, says sustainability can often get pigeonholed into just talking about resource use or economic viability. MTI prefers to use a wholistic, triple-bottom-line definition of sustainability that hinges on people, plant and profit.

“Companies looking to do more to manage for sustainability can look for the intersection between managing for environmental sustainability, managing their people well—both community and employees—and setting up a profitable business model.”

– Kieran Ficken, Sustainability Program Manager for Measure to Improve

Sustainability Benefits and Challenges for Greenhouse Operations

The controlled environment of a greenhouse provides the opportunity to create systems that reduce resource use and utilize clean or renewable energy. However, the cost of labor for carrying out sustainability initiatives and access to infrastructure still create challenges, just like they would in the open fields.

Alex Lopez, Director of Growing Operations for Windset Farms, and Madu discuss some of the innovative systems for efficient resource use at the company’s greenhouses, including the method for reusing condensation water, an adjacent biofilter for the reuse of excess water, solar panels, the use of integrated pest management, the system for efficient reuse of CO2 and the use of thermal screens to reduce energy consumption by 50% to 60% at certain times of the day. (For more details on these systems see 5:30 to 10:10 in the webinar recording.)

Lopez explains that the rising cost of labor contributes to challenges in meeting sustainability initiatives. For instance, in order to recycle the metal support hoops used in the greenhouses at the end of the season, workers would have to remove the twine connected to each hoop, adding a large labor cost to what would otherwise be a straightforward opportunity to recycle materials. He notes that while Windset Farms’ operations have close access to a composting facility and recycling facilities, not all operations will have close access to infrastructure that facilitates the most sustainable practices.

First Steps Toward Sustainability for Any Organization

Ficken explains for all operations whether greenhouse, field or packing shed, the first steps in starting a sustainability program are the same: identify your objective, then choose one or two aligned and manageable topics and start collecting data.

If you’re not sure where to start, Ficken says to think about the why driving you to take action. Is it to be able to answer the questions of an important buyer, a new regulation or something else? She says, “Coming back to why you are doing this will help you narrow in on the purpose of the program and from there, sometimes the answer of what data is needed and what kind of practices you want to see comes out a little bit clearer.”

Focusing your program allows for tracking measurable success and establishing teams and practices that can be applied to achieving new goals in the future. She asserts, “Clarity at the start of your sustainability program is key to being successful in the long run.”

MTI also steers clients clear of the pitfall of overplanning. Getting started, knowing there will be mistakes that need to be corrected along the way moves you closer to your goals than waiting to nail down the perfect fool-proof plan.

And while many projects will start with a core group of people designing new practices, to carry your program forward successfully, all staff need to feel some responsibility for following the sustainability program.

“Being successful is a team effort from all departments. You have to get everyone involved – HR, finance, maintenance – across all your operations. At every level you need to have everyone thinking about reducing, reusing and recycling.”

– Jeff Madu, Vice President of Sales, Windset Farms

The Importance of Data Collection for Measuring Progress

The data you collect tracks your progress and focuses your goals, however, collecting data is expensive and takes time, people and technology. Being sure you are collecting the right data for your goals prevents you from slowing your program by using resources to collect data irrelevant to your goals.

“Data is really at the heart of addressing a sustainability problem and most business problems too. So we can think of managing for sustainability like managing for any other aspect of your business. You need to understand the right metrics to know what kind of progress you’re making.”

– Kieran Ficken, Sustainability Program Manager for Measure to Improve

Beyond the reality that a greenhouse can produce more crops using less land and water resources, greenhouses excel in the data collection phase of managing for sustainability. The clear boundaries on resource use a greenhouse provides make measuring for sustainability impacts simpler and in many cases, because of the controlled environment of the greenhouse, there may already be a process for collecting the data needed. Being able to get and analyze the information quickly means adjustments can be made in real time.

Improvements in Sustainability Over the Next Three to Five Years

Technology will continue to change growing techniques. Lopez explains that even currently, more types of sensors are becoming available to help greenhouse growers get even more information and make better decisions. He projects that artificial intelligence technology and computer assisted growing will help growers make decisions that can increase production and be more energy efficient.

“The improvements I see coming to the industry are connected to a move toward more data-driving growing.”

– Alex Lopez, Director of Growing Operations for Windset Farms

Additionally, over the next three to five years, prices for existing technologies and green electricity will likely continue to drop, making them more available, for instance LED lighting and high pressure sodium lighting. As these light sources become more efficient and affordable, greenhouse growers can extend the growing season into the winter in an energy and cost efficient way.

Madu also mentioned that he expects to see a continued focus on innovative recycled and recyclable packaging that extends the shelf life of the product.

Sustainability as a Whole Industry Move

Sustainability comes with a high price tag in the marketplace. The most sustainable practices are sometimes more costly than standard practice for others in the industry, highlighting the need for an industry-wide movement toward more sustainability.

Madu asserts, “We wanted to be one of the first companies to do the right thing. But, we’re all in this together, the whole industry, and together we need to move forward on how we look at our businesses and become more sustainable.”

MTI often emphasizes to clients, to think of sustainability as “the new food safety.” It’ a cost of doing business, and it’s not going away. Finding ways to involve all industry partners is important because a move to more sustainable practices industry wide is to the benefit of all.

“In order for our produce industry to become more sustainable, it’s not just about greenhouses, it’s not just about one company. It’s about all of us, all of us who are part of the supply chain—retailers, producers, employees, consumers—moving to invest in sustainable practices and embrace this vision of sustainability that encompasses people, planet and profit.”

– Lilian Autler, Senior Workforce Development Facilitator for EFI

The Green Team Project: Reducing Waste in Agriculture Through Worker-Management Collaboration

Program Background

EFI, MTI and Windset Farms have partnered to participate in a pilot program, called Produce and Reduce, which is funded by the California’s Workforce Development Board to mitigate climate change by reducing waste and greenhouse gas emissions in agriculture.

Windset Farms’ pilot program is taking place at its greenhouse operation in Santa Maria, California, and is focused on waste management as a starting point to establish an organizational culture and practices that can then support future sustainability efforts.

The program hinges on the idea that sustainability efforts are enhanced through workforce development training, workforce engagement and efficient data collection and analysis.

Establishing a green team, a trained, core group that includes employees from different areas of work, applies the EFI labor-management collaboration model to waste reduction and planning for continuous improvements in sustainability initiatives and serves as the starting place for creating program practices.

Early Produce and Reduce Program Learnings

For Better Waste Management Practices, Know Your Trash

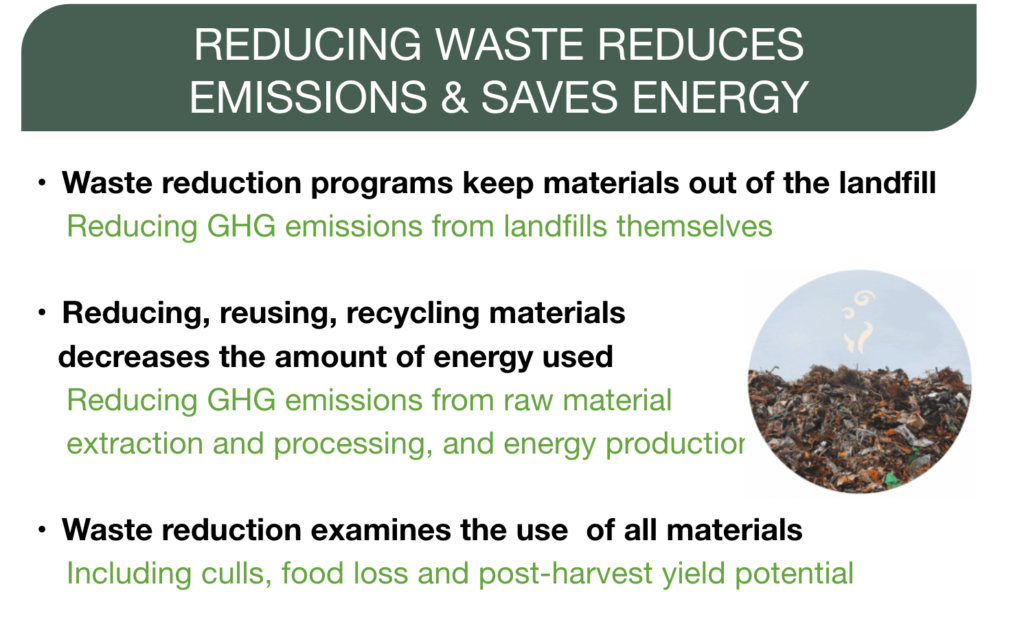

The first phase of the program involved an assessment of all the materials that come through the facility. This includes cardboard, plastics, lunch room trash, construction materials, hairnets, gloves, culls, food waste, etc.

The team participated in a self-audit of 2000 pounds of landfill material and quantified every single thing—basically digging through the trash and to measure and categorize it. According to Lopez, the results were “eyeopening.”

Despite having an existing program for cardboard recycling, the team found that cardboard was still exiting the facility heading for the landfill. This led them to create a new goal of keeping all cardboard out of the landfill.

They also found food waste. By measuring the amount, they had a starting place to take action and move to eliminate food waste going to the landfill. “Not only to reduce pollution that will go out into the environment, but also to be compliant with the new California law SB 1383 that requires all households, residents, business to reduce the amount of food waste going to the landfill,” said Lopez.

Real Time Data Analysis in Action

Another example coming from collecting and analyzing data in the first phase of the program shows how quick analysis can lead to quickly making adjustments to improve practices.

Windset Farms had an existing screening program in place to ensure all compostable materials were sent to the composting facility. After analyzing the data, the team realized that many bins were being trucked from the greenhouse to the composting facility before they reached capacity.

Connect with EFI For More Learnings From the Produce and Reduce Program

EFI will be documenting and sharing learnings from the program in the future. If you’re interested in keeping up with the results of this program, subscribe to EFI’s newsletter.

Other Posts in the People First Series:

Challenges and Opportunities: Rethinking the Way Work is Done Adds Value to the Supply Chain

Solving Labor and Recruitment Challenges: Navigating the H-2A Program

Hiring for the Skills of Tomorrow – Upskilling and Credentialing in Agriculture

Intro to the Ethical Charter on Responsible Labor Practices

How Responsible Recruitment Practices Unlock Competitive Advantage

Myths and Realities of Social Compliance

Summary written by: Amy Beth Dingle, Freelance Writer for EFI