Since the integration of EFI Standards in 2016, Houweling’s greenhouse operation in Camarillo has experienced fewer accidents, cleaner work environments and more fruitful labor-management partnerships.

For Houweling’s Group, EFI means improvements that add value to the supply chain and happier employees at all levels.

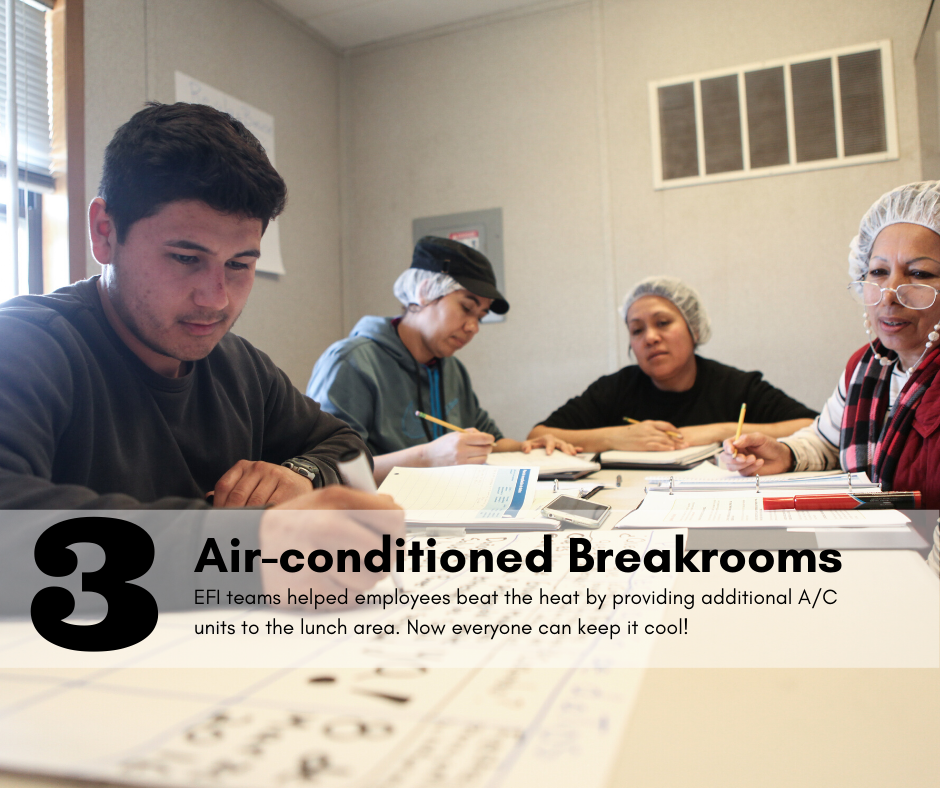

Top Workplace Improvements By EFI Teams at Houweling’s Camarillo:

Workers were having issues with the automated internal transport system. They could sometimes bump into employees, causing a few accidents. The EFI team recommended using the system during certain times of the day when there is less staff in the greenhouse, which has improved road safety onsite. They are currently working on improving the pathways.

Employees feel more comfortable approaching managers and sharing concerns, praises and improvements thanks to this top improvement.

Employees were concerned about the lack of A/C units in the breakroom. A worker brought this up to a member of the EFI Leadership Team and the issue was addressed. Workers can now rest in a cooler environment thanks to this EFI team improvement.

Packhouses at Houweling’s were becoming too warm during California’s summer heat and the issue was raised to members of the EFI Leadership Team. The problem was fixed by replacing fans and cleaning air filters.

Female night workers raised concerns about the lack of illumination in the parking area. Through EFI meetings members were able to come up with a solution and placed light fixtures next to the parking lot. Employees reported feeling safer after these lights were installed.

Packhouse employees were having difficulties processing products because a machine was releasing a lot of smog. To improve air quality, a smog vacuum was installed to prevent workers from breathing that air.

Accident prevention starts by avoiding risks in the greenhouse. The EFI Team is taking action by being vigilant in watching for any cracks on panels and repairing any damaged areas of the glass ceiling.

Through EFI meetings, members are able to share the concerns of the workforce, find the cause of the problems and recommend a solution. Learn more about EFI Leadership Teams.

Related articles:

Farmworkers shine, when given the chance to share ideas

EFI’s Worker Engagement Model Creates Positive Outcomes for Grower-Shippers

Houweling’s Group: Improvements on video

Written by: Rebecca Castrejon, Digital and Communications Associate for EFI